ASME’s latest set of nonmetallic (NM) pressure piping system standards are enabling oil & gas companies to construct safer pipelines more cost-efficiently. An important consideration as new sources of supply, aging infrastructure and other factors are fueling pipeline construction.

ASME’s NM standards provide comprehensive design, installation, inspection, examination and testing guidelines along with material requirements that can help companies make informed decisions. In turn, this can speed-up timelines, saving costs while driving new opportunities forward. ASME’s standards help to provide:

To learn more about our NM standards, sign up for one of our upcoming webinars. And if you’re ready to buy the standards, purchase one or all of the NM standards below.

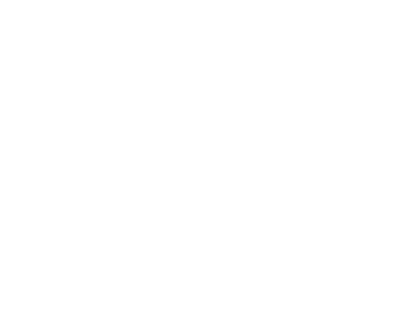

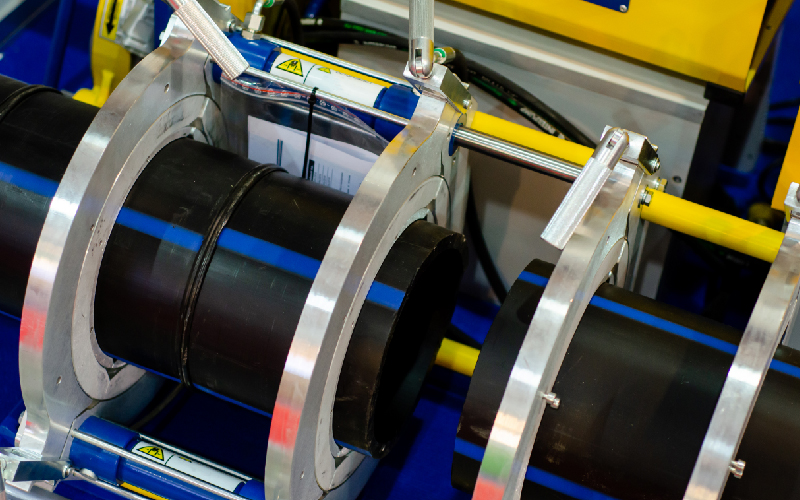

ASME NM.1 prescribes requirements for the design, materials, manufacturing, fabrication, installation, inspection, examination and testing of thermoplastic pressure piping systems. The standard addresses both pipe and piping components that are produced as standard products and custom products that are designed for a specific application.

ASME NM.2 prescribes requirements for the design, materials, manufacturing, fabrication, installation, inspection, examination and testing of glass-fiber-reinforced thermosetting-resin (FRP) piping systems. The standard addresses both pipe and piping components that are produced as standard products and custom products that are designed for a specific application. In addition, the standard allows for a variety of manufacturing methods of FRP pipe and piping components including, but not limited to, contact molding, compression molding, centrifugal casting and filament winding.

ASME NM.3.3 provides tables and data sheets for allowable stresses, mechanical properties (e.g., tensile and yield strength) and physical properties (e.g., coefficient of thermal expansion and modulus of elasticity) for nonmetallic materials.

Sign up for our NM Standards Webinar and explore our nonmetallic pressure piping system standards. Discover nonmetallic material's unique design requirements.

Discover how ASME’s three new nonmetallic standards address the unique design and manufacturing requirements of nonmetallic pressure piping systems.

Discover how ASME’s three new nonmetallic standards address the unique design and construction requirements of nonmetallic pressure piping systems.

Discover the unique requirements for thermoplastic pipe and piping components, addressed by NM.1. And the comprehensive material specs captured in NM.3.

Explore glass-fiber-reinforced thermosetting-resin pipe & piping components distinctive requirements, found in NM.2. And the extensive material specs captured in NM.3.

ASME’s latest nonmetallic (NM) pressure piping standards are educating professionals on how to safely design, manufacture, fabricate, install, inspect, examine and test pressure piping and associated components along with entire pressure piping systems. Explore standards that meet a diverse set of needs, and cover a wide range of applications.

As nonmetallic pipe manufacturers continue to drive growth through innovative new products and manufacturing techniques, it's important to take into consideration new factors that can influence purchase decisions. Deliver solutions that meet with the latest standards and follow industry best practices. Learn more about how ASME’s nonmetallic pressure piping standards can support your business.

This standard applies to stationary reinforced thermoset plastic corrosion resistant vessels used for the storage, accumulation, or processing of corrosive or other substances at pressures not exceeding 15 psig external and/or 15 psig internal above any hydrostatic head.

This standard prescribes minimum requirements for the design, materials, fabrication, erection, test, inspection, operation, and maintenance of piping systems typically found in electric power generating stations, industrial and institutional plants, geothermal heating systems, and central and district heating and cooling systems.

This standard contains requirements for piping typically found in petroleum refineries; chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants; and related processing plants and terminals. It covers materials and components, design, fabrication, assembly, erection, examination, inspection, and testing of piping.

ASME

Two Park Avenue

New York, NY 10016-5990

Email: CustomerCare@asme.org